Specifications

-

Size Range

2"-36" -

Operating Pressure (CWP)

285 psi (WCB), 275 psi (CF8M) -

Disc Materials

ASTM A351 gr. CF8M (Stainless Steel) -

Shaft Materials

ASTM A564 - T630SS -

Mounting Flange

ISO 5211 -

Flange Drilling

ASME B16.1 Class 125, ASME B16.5 Class 150 -

Design Standard

API 609 Category B -

Temperature Range:

-20°F-400°F -

Body Materials

ASTM A216 - GR WCB, ASTM A351 - GR CF8M -

Seat Materials

MPTFE -

Body Style

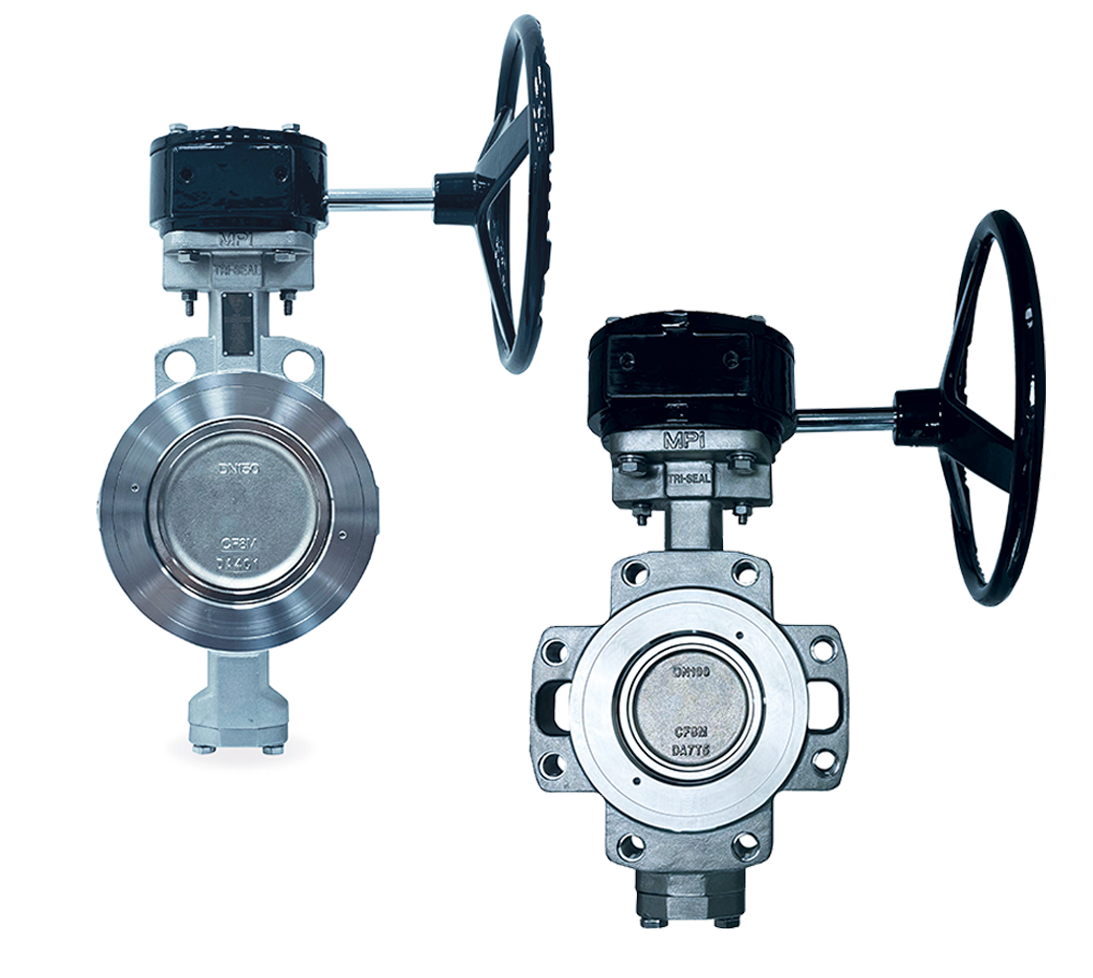

LUG - 2"-36" Wafer - 2"-36" -

Seat Leakage Testing

API 598 -

Certifications

NSF 61/372 -

Face to Face

API 609

Features & Benefits

- RECESSED GLAND: Our recessed gland packing eliminates the requirement for mounting kit and reduces overall package height. A rocker design gland flange and packing gland are utilized to ensure even compression of the packing.

- EXTENDED NECK: Bonnet to flange clearance is a minimum of 2” allowing for piping insulation on all sizes of valves.

- BODY: High quality one-piece casting provides consistent uniformity. Body is available in Wafer or Lug style. Body materials include carbon steel (WCB) and stainless steel (CF8M).

- INTEGRALLY CAST DISC POSITION STOP: Machined position stop in the body locates the disc in the seat to achieve maximum sealing and seat life.

- SEAT RETAINER PLATE: Constructed of the same material as the body, our seat retainer plate assures proper sealing and allows for full rated bi-directional dead end service.

- SHAFT: Our 17-4PH Stainless Steel shaft provides maximum strength and stability for high pressure applications.

- BONNET: Allows for direct mounting of all types of actuation. Standard drilling conforms to ISO 5211.

- PACKING: Multi-layered, V-type PTFE packing allows for even compression against shaft and body, providing a positive seal even under high pressure / high cycle applications.

- BLOWOUT PROOF STEM: Our shaft retention system is designed per API 609 standards.

- SEATS: High Performance Butterfly Valves feature an innovative free-floating, pressure-assisted, solid seat design that ensures a positive seal under both low and high pressure requirements. Unlike traditional valves, our seat does not rely on secondary components like O-rings or springs, resulting in a longer service life with minimal maintenance.

- DISC TAPER PINS: Pins are offset from the center of the stem which places them in compression and gives them a yield point greater than the stem itself.

- DISC: Standard construction is 316 stainless steel. Designed to have minimum deflection and movement under pressure, which reduces torque and improves cycle life. Double offset discs produce a camming motion, allowing it to release from the seat within the first few degrees of opening and reducing wear.

- BEARINGS: Woven fabric steel backed bearings provide excellent load-bearing capabilities, are self lubricating to provide improved wear life, and are tolerant to harsh high pressure applications.